Description

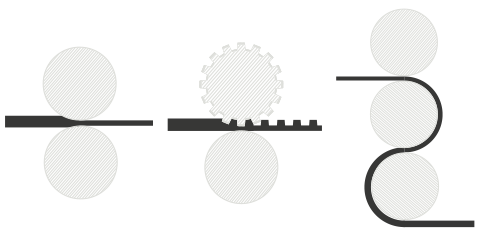

We produce laminating calenders for textiles of any width, embossing calenders for textiles and paper, laboratory calenders with steel rollers with mirror finish or embossed surface, heated or cooled, with rubber, nylon sleeve covered nip roll, with pneumatic or hydraulic pressures up to 60 tons, and complete calendering plants.

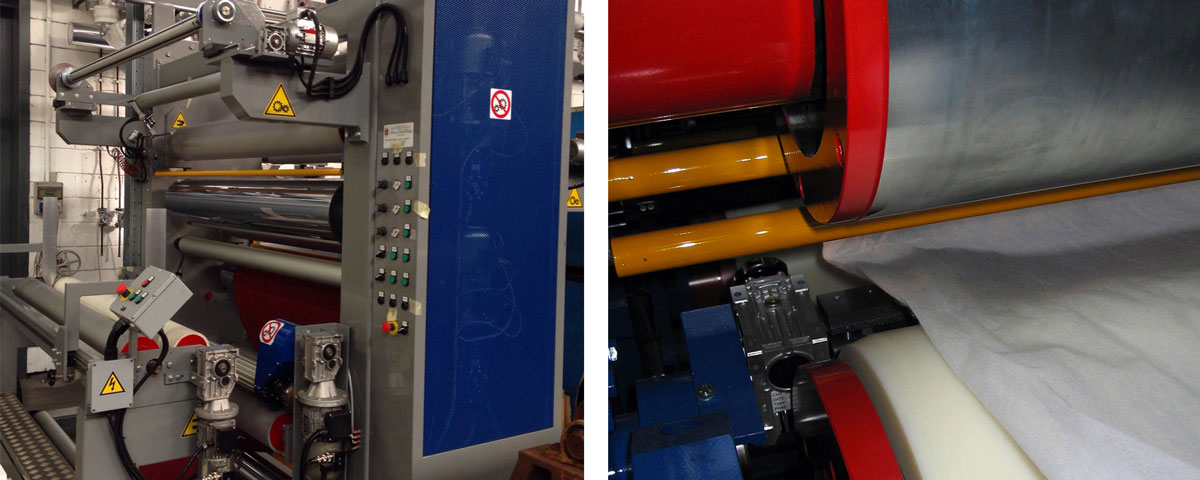

Embossing calender

Smooth or embossed calendering of textiles, tnt, film or paper is possible.

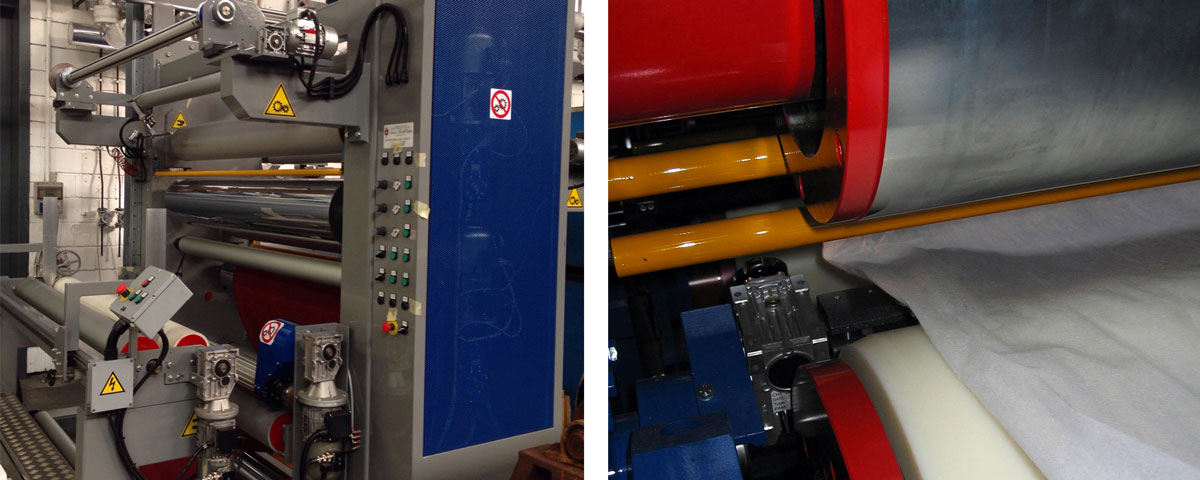

Top roller is ground, chromed and reground to a mirror finish or engraved surface according to production requirements, steel pressure roller with nylon sleeve. Bottom roller can be moved vertically, towards the chromed roller, by a couple of hydraulic cylinders.

Details and strength

The roller is mounted on a couple of lever mechanism so to be quickly and easily removable, should it be changed with an engraved roller.

Modular and compact design, customizable according to client’s requirements.

Web width

From 500 to 6000 mm

Pressure/load

Calendering pressures are adjustable from 6 up to 60 tons.

Mechanical speed

0 – 20 m/min.

Heating

Oil filled and electrical heated roller or with external hot oil generator.

Laboratory calender mod. Calab

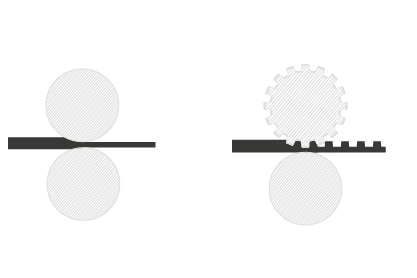

Perfect simulation of different calendering process, with ground heated roll and one bottom, nylon sleeve covered roller.

The top roller is ground, chromed and reground to a mirror finish surface or engraved according to production requirements.

The bottom roll can be moved vertically, towards the chromed roller, by a couple of hydraulic cylinders.

Details and strength

Calendering of fabric samples with pressures from 35 up to 160 kg / cm

The roller is mounted on a couple of lever mechanism so to be quickly and easily removable in case it have to be changed with an engraved roller

Roll face width

500 mm.

Mechanical speed

3 – 15 m/min

Heating

Oil filled and electrical heated roller or with external hot oil generator.