Description

“Antonio & fratelli Zappa” has designed and manufactured coating heads and complete coating lines for over 70 years, selling and testing them in Italy and abroad.

Research and improving on our coating heads, thanks to the collaboration with our clients, allowed us to produce extremely advanced models, appreciated and recognizable all over the world for their precision and versatility.

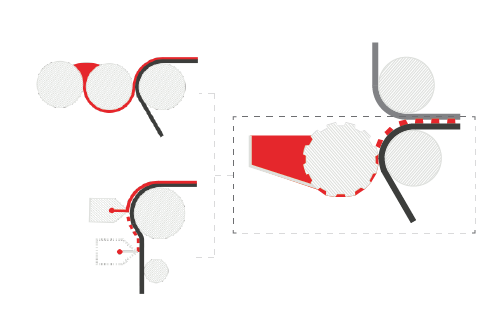

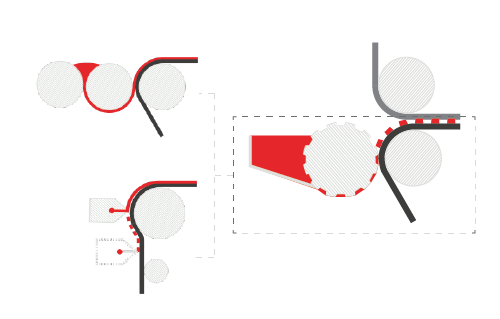

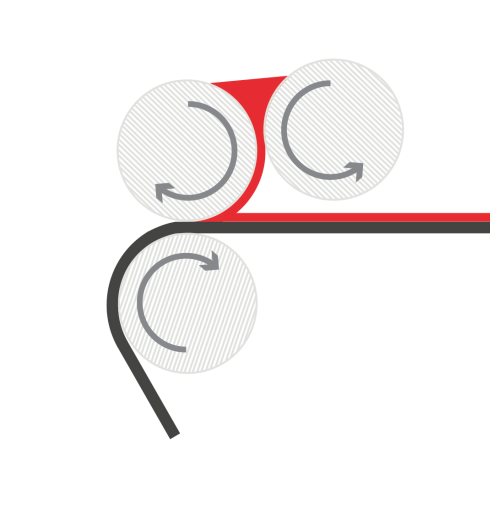

Hot melt lamination head mod. PUR3

Thermo-adhesive hot melt and reactive polyurethane lamination of fabric, jersey, elastic fabric, film, breathable membranes, foam and abrasive sponges is possible.

The machine can be equipped with drum melter for reactive polyurethanes, in 200 liters barrels or with tank melter or extruder for adhesive in cips or thermo-adhesive powders, or with other accessories.

Different engraved lamination rollers can be supplied

Details and strength

Extremely compact unit for minimum amount of space

The machine can be installed in existing lines or it can be supplied with unwind and rewind unit directly mounted on machine frame

Web width

From 500 up to 3000 mm

Mechanical speed

0 – 40 m/min (or more according to client’s requirement)

Heating

Oil filled and electrical heated roller or with external hot oil generator.

Hot melt lamination head mod. PUR4

More sophisticated and advanced model within the range of hot-melt lamination machines, especially designed for breathable membranes lamination.

Thermo-adhesive hot melt and reactive polyurethane lamination of fabric, jersey, elastic fabric, film, breathable membranes, foams and abrasive sponges is possible.

The machine can be equipped with drum melter for reactive polyurethanes, in 200 liters barrels.

Different engraved lamination rollers can be supplied.

Details and strength

Especially designed for breathable membranes lamination

Wide possibilities of customization according to client’s requirements.

Equipped with the most innovative and sophisticated devices for the automatic tension control for unwinding and rewinding of products, allowing an easy and smooth work on elastic fabrics.

Web width

From 500 up to 3000 mm

Mechanical speed

0 – 40 m/min (or more according to client’s requirement)

Heating

Oil filled and electrical heated roller or with external hot oil generator.

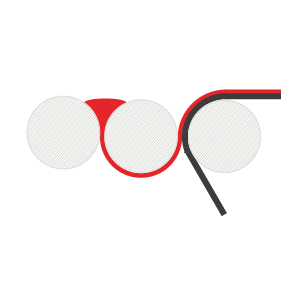

Laboratory coater mod. “PURlab”

Hot-melt laboratory coater for reactive polyurethane adhesives (PUR). It perfectly replicates performances and productions of the well-known PUR3 and PUR4 from the Zappa range.

It works both as multiroll or gravure coater, offering perfect solutions for research & development departments, research institutes, universities, etc…

Details and strength

Fully equipped and compact machine with unwinds, rewind and work table in order to coat rigid panels

Web width

500 mm.

350 mm.

Mechanical speed

0 – 25 m/min

Heating

Oil filled and electrical heated roller or with external hot oil generator.

Multi-roller coating an laminating unit for rigid panel mod. TMP-coat

Very easy and useful machine able to coat rigid panel, high viscosity foam and rigid material and laminate with film, fabric or other flexible support. Complete of conveyor belt or support motorized rollers. The machine can be equipped with drum melter for reactive polyurethanes, in 20 or 200 liters barrels

Details and strength

Fully equipped and compact machine with unwinds, rewind and work table in order to coat rigid panels

Web width

from 500 mm to 1600 mm

Mechanical speed

0 – 25 m/min

Heating

Oil filled and electrical heated roller or with external hot oil generator.

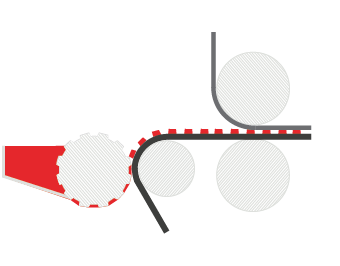

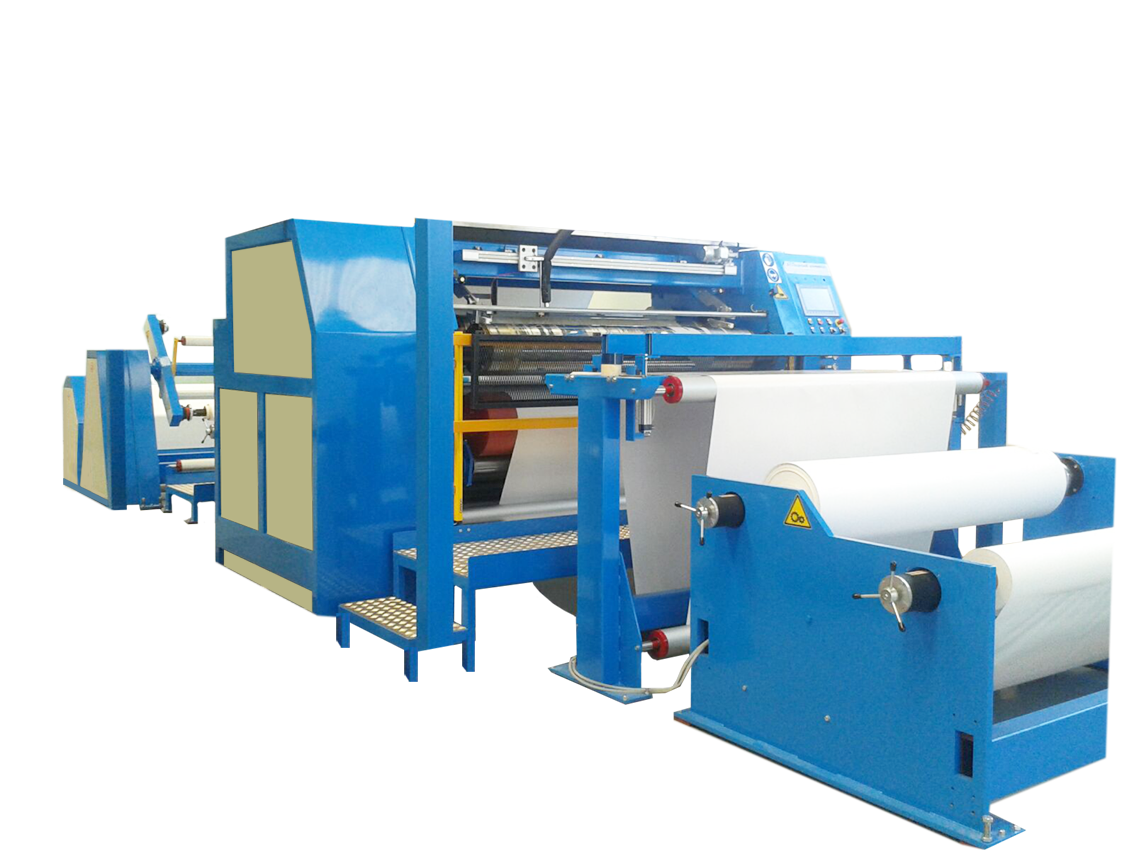

Hot melt multi-roller coating and laminating machine mod. TM-coat

Thermo-adesive hotmelt (PA,PP,TPU), hotmelt self-adhesive PSA and Reactive Polyurethane PUR full cover coating of fabric, jersey, film, paper.

Field of application composite industry, shoe toe, airbag fabrics, upholstery fabric.

The machine can be equipped with drum melter for reactive polyurethanes, in 200 liters barrels or with tank melter or extruder for adhesive in chips. The machine can be installed on existing lines or it can be supplied with unwind, rewind or other devices such as accumulator and turrect winder for no-stop production. Production temperature from 50°C to 250°C.

Details and strength

User friendly, very compact machine, full coating technology.

Web width

from 500 mm to 2500 mm

Mechanical speed

from 0 – 50 m/min

Heating

Oil filled and electrical heated roller.

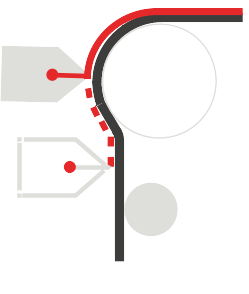

Slot dye coating and laminating machine mod. D-coat

Slot dye is a device capable of holding a fluid’s in temperature, distributing the fluid uniformly and defining a coating width. Can work on air or against the beck up roller. The Dye is comprised of steel body sections that house the fluid flow chamber. This type of coating are widely used in textile industry mainly for show industry , home textile, technical textile or automotive industry. The production line is complete of unwinder, winder, recovering self-alignment winder for siliconized paper, splicing table and other no-stop devices if required. The process is usually conducted by coating the siliconize paper then laminated on textile support by calendering unit. Thermo-adesive hotmelt (PA, PP, TPU), hotmelt self-adhesive PSA and Reactive Polyurethane PUR full cover coating are recommended. Production temperature from 50°C to 220°C.

Details and strength

User friendly, compact machine, Coating full coating, stripe breathable coating, coating weight min. min 20 g/sqm

Web width

from 500 up to 2200 mm.

Mechanical speed

0 – 60 m/min

Heating

electrically heated.