Description

With over 150 years of experience, our company is qualified in researching and designing new machinery and prototypes for advanced and innovative lines of production in the textile industry and many more, such as industrial automation and lab lines with different combinations.

Customization, research and development, investigation of superior client-tailored solutions are our real strength, reflecting the dynamism and versatility that this company has developed during its history.

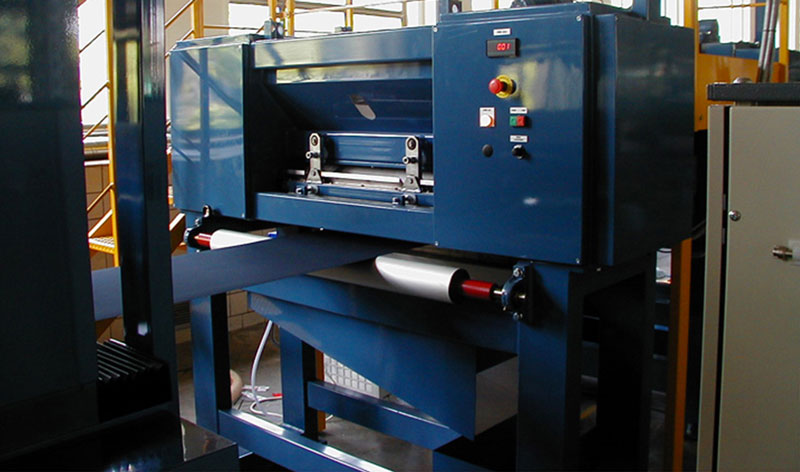

Laboratory calender mod. “Calab”

Perfect simulation of different calendering process, with ground heated roll and one bottom, nylon sleeve covered roller.

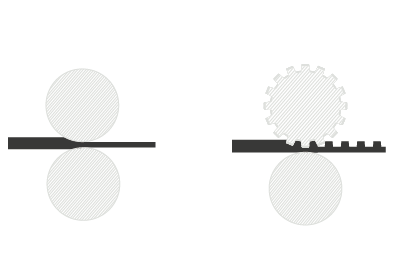

The top roller is ground, chromed and reground to a mirror finish surface or engraved according to production requirements.

The bottom roll can be moved vertically, towards the chromed roller, by a couple of hydraulic cylinders.

Details and strength

Calendering of fabric samples with pressures from 35 up to 160 kg / cm

The roller is mounted on a couple of lever mechanism so to be quickly and easily removable in case it have to be changed with an engraved roller.

Roll face width

500 mm.

Mechanical speed

3 – 15 m/min

Pressure/Load

Pressures are adjustable from 2 up to 8 tons.

Heating

Oil filled and electrical heated roller or with external hot oil generator.

Laboratory coater mod: PUR-Lab

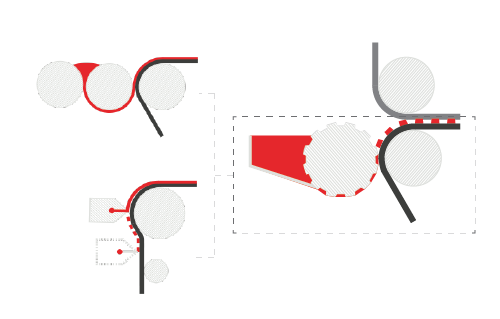

Hot-melt laboratory coater for reactive polyurethane adhesives (PUR). It perfectly replicates performances and productions of the well-known PUR3 and PUR4 from the Zappa range.

It works both as multiroll or gravure coater, offering perfect solutions for research & development departments, research institutes, universities, etc…

Details and strength

Fully equipped and compact machine with unwinds, rewind and work table in order to coat rigid panels.

Web width

500 mm.

350 mm.

Mechanical speed

0 – 25 m/min

Heating

Oil filled and electrical heated roller or with external hot oil generator.